The construction industry isn’t the first thing that comes to mind when you think of emerging technologies. However, in a bid to respond effectively to pressures such as the skilled labor shortage and new sustainability regulations, the industry has responded in some incredibly exciting ways.

Advanced technologies and construction software are not only cutting costs, increasing productivity and leading to great projects being completed, they are also reducing safety hazards and construction risks, effectively cutting the incidence of workplace injuries. And it’s not just how we build that’s changing, but what we build with. Read on to find out about the 10 biggest construction technology trends.

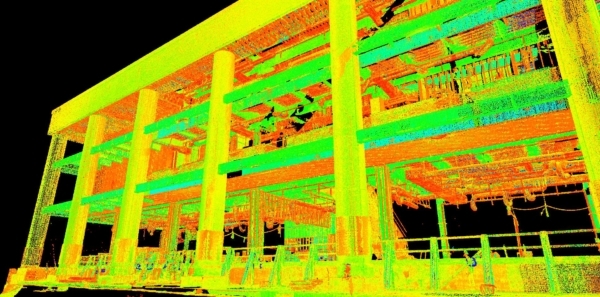

LiDAR, or Light Detection And Ranging

LiDAR technology enables sensors to scan a construction site and create high-resolution 3D images in real-time. This makes it feasible to perform construction work from a distance. The value of this type of planning has been heightened by the development of digital collaboration frameworks such as BIM, which deliver the value of these scans to every part of a construction team in the best formats.

LiDAR was previously used in the mapping of Notre Dame cathedral. These scans were referred to in 2019 after a fire destroyed the spire and much of the main structure. Combined with scans of the destroyed building, a restoration map has been created.

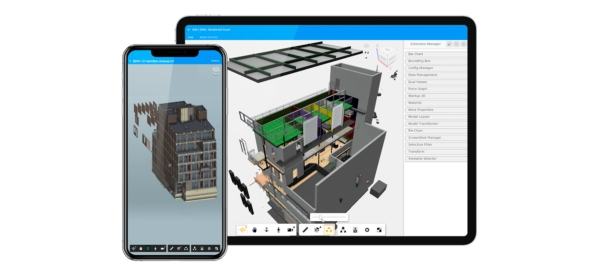

BIM software

BIM stands for Building Information Modelling and it is a big step up from CAD or Computer-Aided Design. BIM is able to create more than just a 3D model. The models contain important information that is actionable within each model. When a building originally designed with BIM software needs to be remodeled or renovated, it is a much easier task than before.

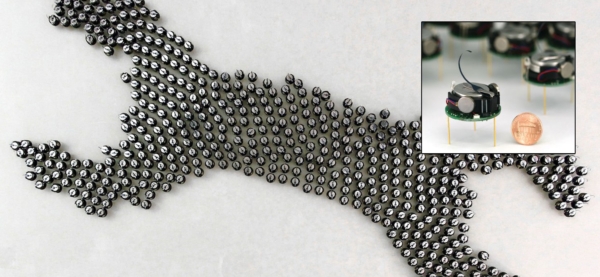

Robotic swarms and humanoid workers

Robot swarms consist of hundreds of little robots that are designed to work together – similar to a group of insects. Think of them as the robotic equivalent to an army of leaf cutter ants. These small but mighty workers are useful for repetitive tasks such as bricklaying and can be deployed to difficult-to-reach locations that are dangerous or even impossible for human workers, such as the bottom of the ocean or even other planets.

Unlike robotic swarms, humanoid worker robots are built to resemble humans. Japanese researchers have developed the HRP-5P, a humanoid robot capable of performing basic physical tasks like installing drywall.

Technology that takes the weight off

In contrast to autonomous robots, which effectively assist the human construction worker, The MULE (Material Unit Lift Enhancer) is here to give a helping hand. The lift assist device helps workers load and place heavy material and is designed for handling material that weighs up to 135 lbs. This machine doesn’t replace but instead supplements the efforts of human laborers, safeguarding them from potential back injuries and helping them carry out uncomfortable, repetitive movements.

Construction drones

Useful for conducting aerial mapping surveys, drones can decrease the amount of time needed to produce an accurate survey. They also eliminate some of the human error in the process and can be used for dangerous tasks, such as taking measurements in hard-to-reach areas. Like robots, drones can effectively cut costs and increase safety

Smart hats and brainy boots

Wearable technology is no longer reserved for gamers. Shimabun, a Japanese company, recently released an upgrade kit that can be used to equip standard hardhats worn by construction workers. The kitted out hats can monitor motion, location and even temperature, sending an alert when a worker might be overheated. The hats are also able to tell when a worker falls and can be programmed to trigger an emergency call. The data collected by these hats can also be used to monitor and analyze mistakes made onsite, in order to make future improvements.

As well as smart hats, wearable tech in the construction industry has now extended to footwear. SmartBoost sensors in boots identify workers when they enter a site, measure a worker’s energy levels and can alert first responders in an emergency situation. They also enable the construction project manager or general contractor to assign tasks via mobile.

VR construction training

In the aviation industry, virtual reality training is commonplace. The construction industry has picked up on this and is introducing this type of training as a more engaging way to teach construction skills than traditional classroom-based lessons or video learning. VR also allows trainers to create simulations of situations that are too risky to replicate, like an onsite equipment malfunction. There is also the potential for VR and AR to be incorporated into project management software.

Wearable AR

With AR, workers can see layers of plans and data while on-site by using a camera-equipped mobile device or wearable lenses. Augmented reality construction glasses such as the Microsoft Hololens, give workers hands-free access to building plans, can take distance measurements, as well as generate models from surrounding site scans.

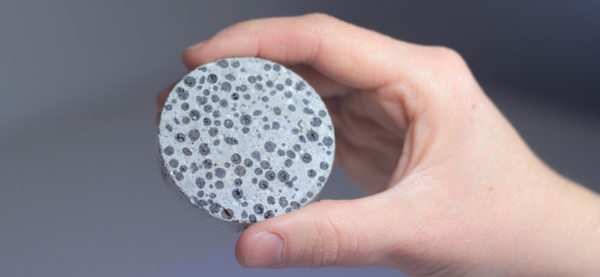

The future of concrete

It’s not just how we build in 2020 that is changing, it is what we build with. Let’s start with the emergence of self-healing concrete that can repair its own cracks and last up to 200 years! This clever concrete is built with microcapsules that contain healing agents, such as minerals, epoxy, or polyurethane. Another new adaptation to concrete is concrete which is embedded with microscopic glass balls that reflect light sources to emit light, creating an aesthetically attractive effect. This also has the potential to be used in signage systems and for building in areas where light is limited.

Augmented wood

A new type of augmented wood that is up to 90% transparent can offer an alternative to glass for windows that is stronger, provides more insulation, and is biodegradable.

‘By selectively extracting wood’s lignin – the substance that makes up its cell walls – and replacing it with a specific type of polymer, it becomes a new material. (This wood) is weather-proof, more fire-resistant, three to five times stronger, and transparent.’ Timothée Boitouzet, Founder of WOODOO, a company specializing in augmented wood.

These emerging construction technologies have a big part to play in transforming the construction project life cycle, from fast-tracking the construction schedule for a newbuild to creating buildings that are environmentally efficient and sustainable by building with new hybrid materials.